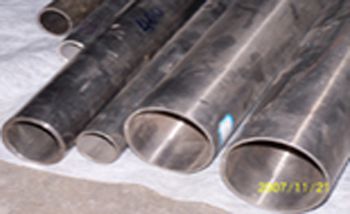

Seamless Ni200/Ni201 Tube/Pipe

Strictly implements the Technical specification of ASTM B161/ASME SB161 and ASTM B163/ASME SB163

Features:

1- Grades: Nickel 200(UNS02200), Nickel 201(UNS02201)

2- Size ranges:

OD.: 4 to 168mm W. T.: 0.5 to 12mm Length: Within 13500mm

3- Applications: Chemical processing, Marine Engineering, Power Generation, Oil and Gas Extraction, Petrochemical processing, Telecomminications Etc.

Ni200/Ni 201 Plate/Sheet

We can provide nickel plate as per your requirements.

1- Ni200,Ni201 N4, N6, N7

2- NCu28-2.5-1.5, NCu40-2-1

3- Condition of delivery: MY

4- Spec (thickness x width x length):

0.5-40 mmx 100-1, 220 mmx 100-4, 000mm

Monel 400

Monel 400 Chemical composition

|

Alloy

|

%

|

Ni

|

Cu

|

Fe

|

C

|

Mn

|

Si

|

S

|

|

Monel400

|

Min.

|

63

|

28

|

|

|

|

|

|

|

Max.

|

|

34

|

2.5

|

0.3

|

2

|

0.5

|

0.024

|

Monel 400 Physical properties

|

Density

|

8.83 g/cm³

|

|

Melting point

|

1300-1390 ℃

|

Monel 400 Alloy minimum mechanical properties in the room temperature

|

Alloy state

|

Tensile

strength

Rm N/mm²

|

Yield

strength

R P0. 2 N/mm²

|

Elongation

A 5 %

|

|

Monel400

|

480

|

170

|

35

|

Characteristic as below:

Monel 400 is an extremely combination property that use for largest amount and most widely corrosion resistance alloy. This alloy in the hydrofluoric acid and fluoride gas medium with excellent corrosion resistance, as well as to the hot concentrated alkali. At the same time, is also corrosion resistant to neutral solution, sea water, air, organic compounds. An important feature of this is generally do not generate a stress corrosion cracking, good cutting performance.

Monel 400 Metallurgical structure

Monel 400 alloy is high-intensity single-phase solid solution.

Monel 400 Corrosion resistance

Monel 400 alloy in the fluoride gas, hydrochloric acid, sulfuric acid, hydrofluoric acid and their derivatives have a very good corrosion resistance property, and possess better corrosion resistance more than the

copper alloy in the sea water. Acid medium: Monel 400 have corrosion resistance in less than 85% consistency of sulfuric acid. Monel 400 is an important material that resistant to hydrofluoric acid. Water corrosion: Monel 400 alloy in most corrosion cases of water, not only excellent corrosion resistance, but also less pitting, stress corrosion, the corrosion rate less than 0.025mm / a. High temperature corrosion: Monel 400 for the work of the highest temperature at about 600 ℃ in general in the air, in the high temperature steam, the corrosion rate less than 0.026mm / a. Ammonia: Monel 400 can be resistant to an hydrous ammonia and aminate conditions corrosion below 585 ℃ due to the high nickel.

Monel 400 Application field:

Monel 400 alloy is a multi-purpose material in many industrial applications:

1. Seamless water pipe in the power factory

2. Sea-water exchanger and evaporator

3. Sulfuric acid and hydrochloric acid environment

4. Sea-water in the use of equipment and propeller

shaft

5. Nuclear industry and used in the manufacture of uranium enrichment isotope separation equipment

6. Manufacturing hydrochloric acid equipment used in the production of pump and valve